|

HEIGHT |

0.00 m |

|

INCLUDED |

0.00 m |

|

USEFUL WIDTH |

0.00 m |

|

LENGTH |

0.00 m |

|

WEIGHT |

0 Kg |

|

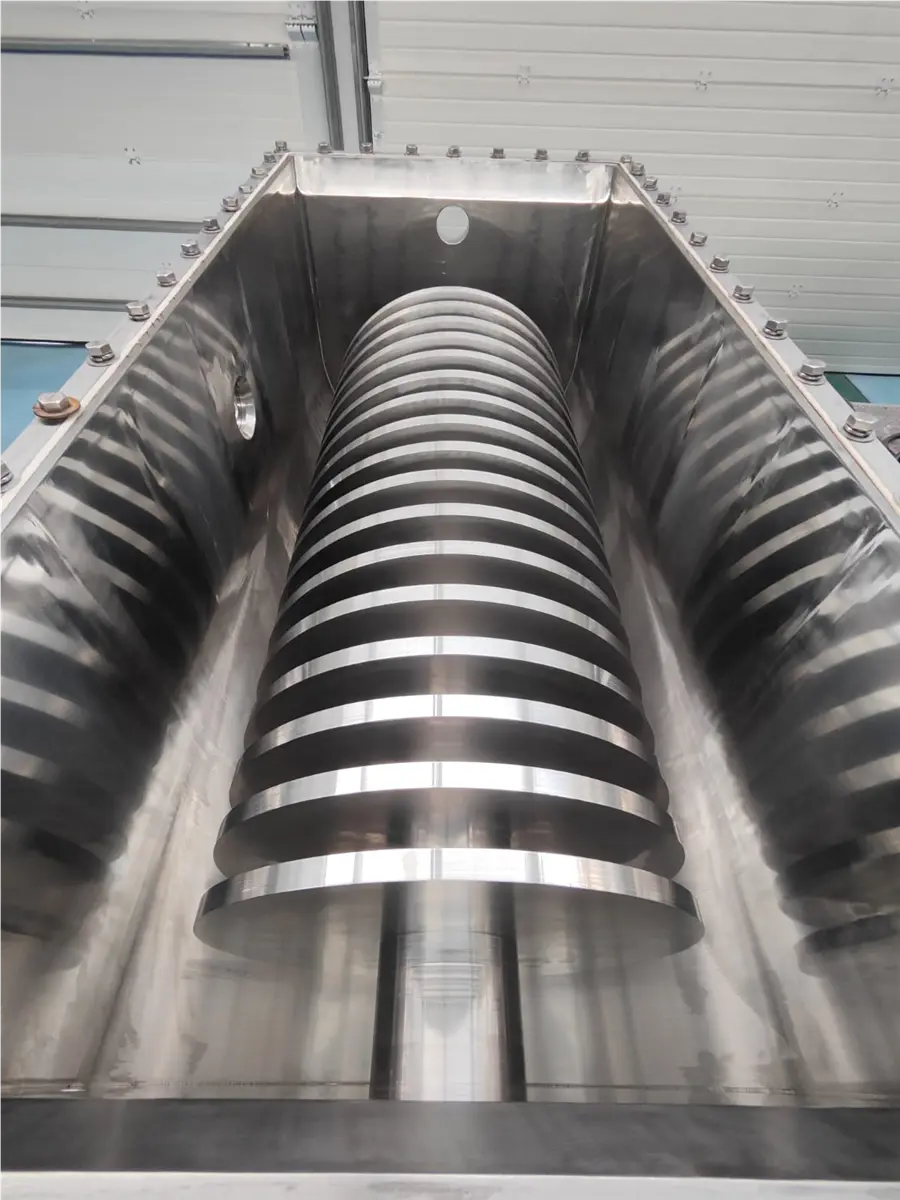

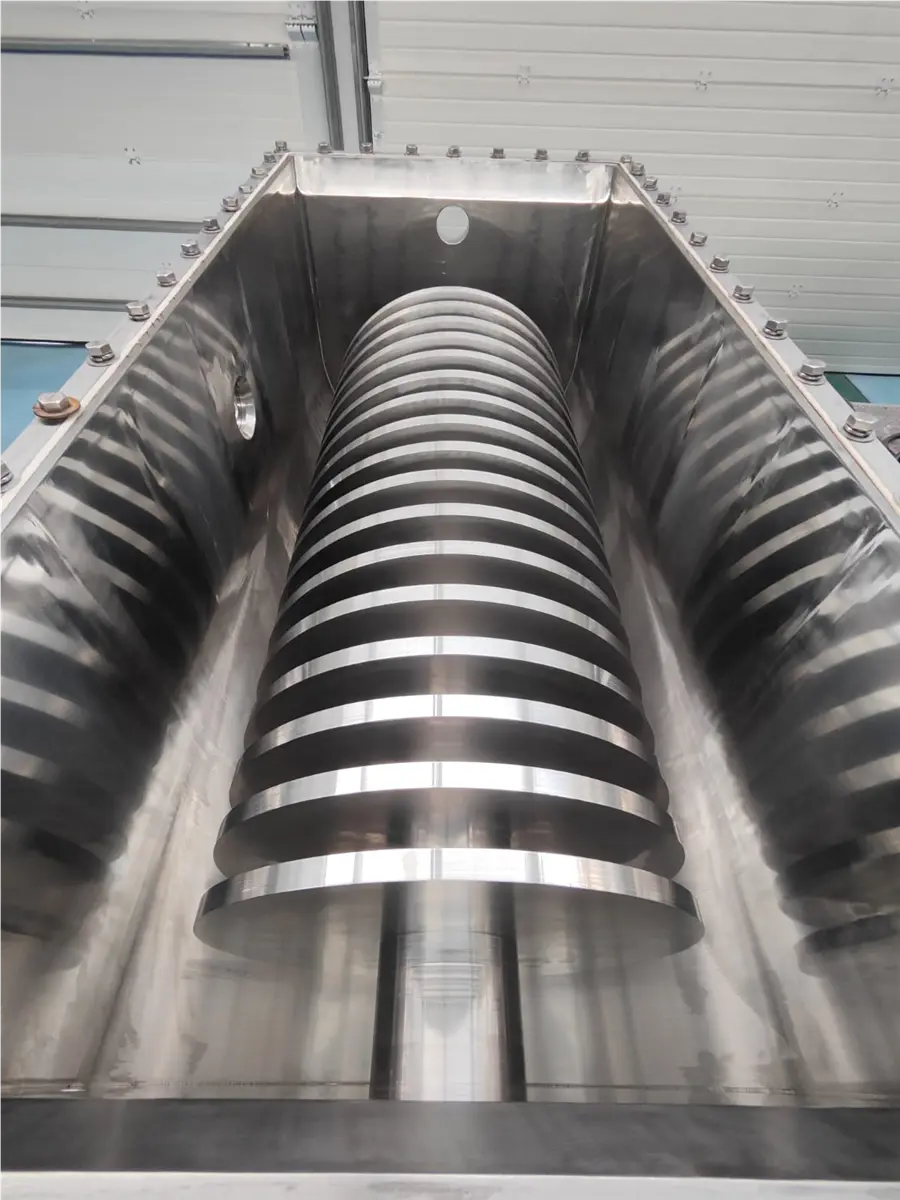

MAKE |

HRS SPIRATUBE |

|

CAPACITY |

1000 L |

|

FLUID |

HIGH VISCOSITY |

|

PLATE NUMBER |

17 |

We speak your language